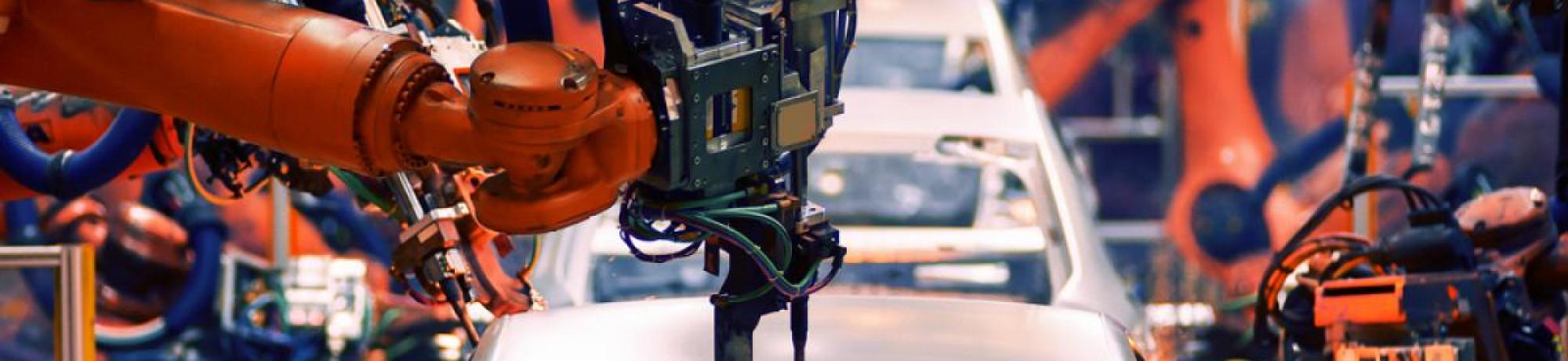

Despite public’s image on extensive use of automation in 21st century’s production lines, currently very limited activities on factory floors are automated. In automotive industry for example, currently less than 5% of the final assembly is automated, relying on manual operators for the remaining 95% of the tasks. The need for automation has always been highlighted by the industry, but the very much needed resolution to bring about significant changes to the factory floors has been missing. With recent developments and subsequent repercussions of COVID19 on various industries, the importance of automation cannot be overemphasized. Due to overcrowded assembly lines, with manual operators working side by side, many production lines had to close down to meet CDC’s COVID19 guidelines regarding social distancing. These factories could remain operational if only they had higher levels of automation in place. This expensive and dramatic experience left no room for procrastination and made extensive automation an indispensable part of future as well as the current factories.

Assembly of Complex Components:

In this research we rely on deep learning and Bayesian Assisted Inference (BAI) to precisely localize (~1 mm displacement accuracy, <0.1 degree rotation) assembly parts in 3D space and plan/execute assembly trajectory accordingly.

Pure Displacement Measurement

Pure Rotation Measurement

Assembly of Mustang dash-trim on dashboard